C.H.C RUBBISH CHUTES ARE MANUFACTURED OF HIGH DENSITY POLYPROPYLENE 750MM ID TUBE SECTIONS SPIGOTED, CHAINED AND BOLTED TOGETHER.

C.H.C RUBBISH CHUTES ARE MANUFACTURED OF HIGH DENSITY POLYPROPYLENE 750MM ID TUBE SECTIONS SPIGOTED, CHAINED AND BOLTED TOGETHER.

THE MAXIMUM RECOMMENDED LENGTH IS 30 METRES AND THE CHUTES CANNOT BE BENT OR TWISTED IN ANY MANNER RATHER MUST HANG VERTICALLY

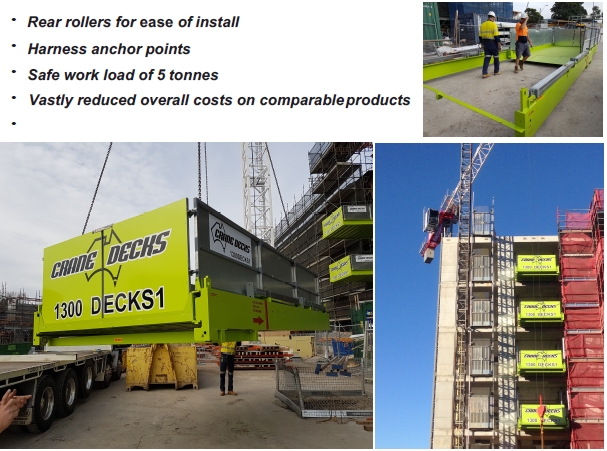

THE IDEAL METHOD OF ATTACHMENT OF THE CHUTES IS BY CHAINS ATTACHED TO EXISTING SCAFFOLDS IN TWO PLACES PER 5 METRE SECTION, AND BY SINGLE SCAFFOLD PIPE FRAME SURROUNDING THE TUBE EVERY 5 METRES PREFERABLYS CARRYING SOME OF THE WEIGHT THROUGH SPECIAL LUGS ON CLAMPS OR PIPES BEING INSERTED BETWEEN THE CHAIN AND THE TUBE.

ALL INSTALLATION MUST BE MADE BY A CRANE

THE CHUTES ARE CUSTOM MANUFACTURED IN THE BASE YARD, TO SITE AND CLIENT REQUIREMENTS. USUALLY IN 4/5/6 METRES LENGTHS. THESE CAN BE JOINED TOGETHER ON SITE BEFORE ERECTION OR HUNG STAGE BY STAGE SPIGOTED ON SITE. IF THIS METHOD IS USED, THEN IT IS PREFERABLE TO TILT THE TOP SECTION SLIGHTLY SO THAT THE OUTSIDE EDGE ENTERS THE SPIGOT FIRST THEN BRINGING THE TOP TOWARDS THE BUILDING ENABLEING THE FITTER/INSTALLER, WHO HAS SAFETY HARNESS ON, TO LEVER THE SPIGOT TOGETHER ON THE BUILDING SIDE.

THE CHUTES ARE CUSTOM MANUFACTURED IN THE BASE YARD, TO SITE AND CLIENT REQUIREMENTS. USUALLY IN 4/5/6 METRES LENGTHS. THESE CAN BE JOINED TOGETHER ON SITE BEFORE ERECTION OR HUNG STAGE BY STAGE SPIGOTED ON SITE. IF THIS METHOD IS USED, THEN IT IS PREFERABLE TO TILT THE TOP SECTION SLIGHTLY SO THAT THE OUTSIDE EDGE ENTERS THE SPIGOT FIRST THEN BRINGING THE TOP TOWARDS THE BUILDING ENABLEING THE FITTER/INSTALLER, WHO HAS SAFETY HARNESS ON, TO LEVER THE SPIGOT TOGETHER ON THE BUILDING SIDE.

EACH CUSTOM BUILT SECTION HAS A TWO PAIR OFATTACHMENT CHAINS TWO METRES LONG ONE FROM EACH END. THE METHOD OF ATTACHMENT IS TO HOIST THE SECTION SLIGHTLY HIGHER THAN NEEDED, ATTACH THE CHAINS TO THE SCAFFOLD TIGHTLY ENSURING THAT EACH CHAIN CARRIES THE LOAD WHEN RELEASED. AT THIS STAGE THE SUPPORTING PIPE FRAMES SHOULD BE PLACED.

TO BE WATCHED IS THAT SOMETIMES THE CHUTE ENTRIES ARE LOAD CARRYING AS THEY ARE LOWERED ON TO THE SCAFFOLD, THIS IS ACCEPTABLE.

EACH SECTION, WHEN ASSEMBLED IN SITU, SHOULD BE SELF SUPPORTING NOT RELYING ON THE LOWER SECTION TO CARRY THE WEIGHT

C.H.C RUBBISH CHUTES ARE MANUFACTURED OF HIGH DENSITY POLYPROPYLENE 750MM ID TUBE SECTIONS SPIGOTED, CHAINED AND BOLTED TOGETHER.

C.H.C RUBBISH CHUTES ARE MANUFACTURED OF HIGH DENSITY POLYPROPYLENE 750MM ID TUBE SECTIONS SPIGOTED, CHAINED AND BOLTED TOGETHER. THE CHUTES ARE CUSTOM MANUFACTURED IN THE BASE YARD, TO SITE AND CLIENT REQUIREMENTS. USUALLY IN 4/5/6 METRES LENGTHS. THESE CAN BE JOINED TOGETHER ON SITE BEFORE ERECTION OR HUNG STAGE BY STAGE SPIGOTED ON SITE. IF THIS METHOD IS USED, THEN IT IS PREFERABLE TO TILT THE TOP SECTION SLIGHTLY SO THAT THE OUTSIDE EDGE ENTERS THE SPIGOT FIRST THEN BRINGING THE TOP TOWARDS THE BUILDING ENABLEING THE FITTER/INSTALLER, WHO HAS SAFETY HARNESS ON, TO LEVER THE SPIGOT TOGETHER ON THE BUILDING SIDE.

THE CHUTES ARE CUSTOM MANUFACTURED IN THE BASE YARD, TO SITE AND CLIENT REQUIREMENTS. USUALLY IN 4/5/6 METRES LENGTHS. THESE CAN BE JOINED TOGETHER ON SITE BEFORE ERECTION OR HUNG STAGE BY STAGE SPIGOTED ON SITE. IF THIS METHOD IS USED, THEN IT IS PREFERABLE TO TILT THE TOP SECTION SLIGHTLY SO THAT THE OUTSIDE EDGE ENTERS THE SPIGOT FIRST THEN BRINGING THE TOP TOWARDS THE BUILDING ENABLEING THE FITTER/INSTALLER, WHO HAS SAFETY HARNESS ON, TO LEVER THE SPIGOT TOGETHER ON THE BUILDING SIDE.